Nano Tungstic Acid for Lithium Ion Battery

High nickel NCM lithium battery is the mainstream direction of electric car batteries. The increase in nickel content has the following effects on the material properties:

(1) The higher the nickel content, the higher the specific capacity of the material. The specific capacity of NCM811 material can reach 210mAh/g, which is nearly 25% higher than that of NCMIII material.

(2) The higher the nickel content, the more difficult it is to store and develop materials. The high nickel ternary material is very easy to absorb water and deteriorate, reducing the capacity and cycle life. In addition, a part of the water will also be stored in the crystal, causing the battery to generate gas in a high-temperature environment, causing the battery to swell and bring safety hazards.

(3) The higher the nickel content, the worse the thermal stability of the ternary material. For example, NCMIII material decomposes at around 300C, while NCM811 decomposes at around 220°C.

(4) Increased nickel content will bring about electrolyte matching problems. The LiOH and other substances produced on the surface of high nickel materials due to water absorption and deterioration will react with the electrolyte, causing capacity degradation and safety issues. Therefore, the modification technology of high nickel materials is an important development direction. Modification techniques include doping with other elements, surface coating, etc., such as nano-coating on the surface of particles with conductive polymers or inorganic materials, which can increase cycle life, improve high-temperature performance and safety.

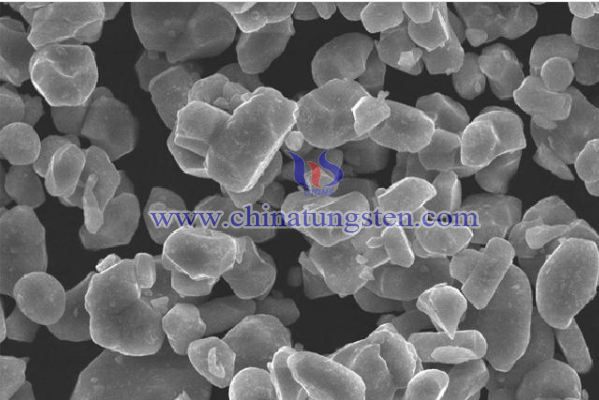

Nano tungstic acid is an inorganic material with a large specific surface area and good electrical conductivity. It has been used in high-nickel batteries for nano-coating on the surface of particles to improve battery performance and safety.